The Growing Challenges of Traditional Tank Cleaning

Tank cleaning is a critical maintenance task across offshore, maritime, and industrial environments. Whether dealing with storage tanks, process tanks, or offshore installations, operators face the same fundamental challenges: hazardous confined spaces, heavy residues, and strict safety requirements.

Traditional tank cleaning methods typically involve manual entry, scaffolding, and high-pressure water blasting. These processes are time-consuming, labor-intensive, and expose personnel to significant risks. Confined space entry remains one of the most dangerous industrial activities, with hazards including toxic atmospheres, limited oxygen, heat stress, and restricted escape routes.

At the same time, operators are under increasing pressure to reduce downtime, lower operational costs, and meet environmental regulations. These combined pressures are driving a shift toward automation and robotics.

Robotic tank cleaning is emerging as the preferred alternative.

What Is Robotic Tank Cleaning?

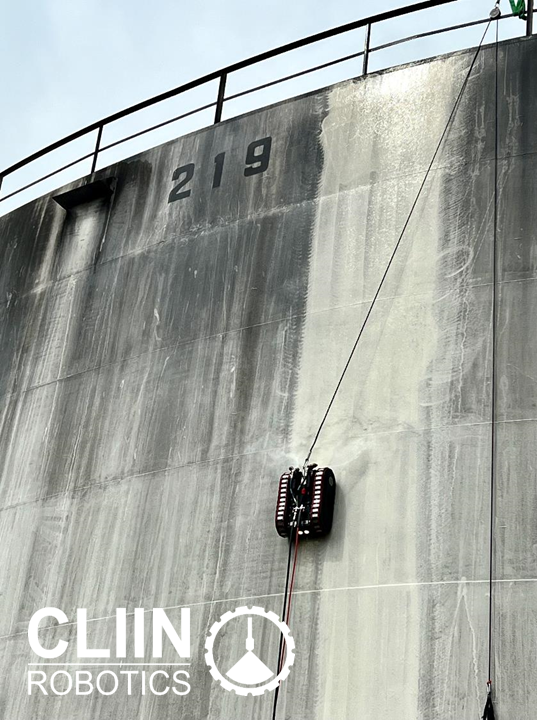

Robotic tank cleaning uses a crawler-based robotic system equipped with a specialized cleaning tool to remove residues from tank surfaces.

In most operations, the operator remains inside the tank but stands safely on the tank floor with direct line-of-sight to the robot. The control unit is connected to the crawler via cable, allowing precise control while avoiding work at height or on temporary scaffolding.

The robotic crawler uses magnetic adhesion to maintain contact with underlying steel structures. This allows operation on painted, coated, and even non-magnetic surface layers where steel is present beneath, enabling vertical and overhead movement in a wide range of industrial and offshore environments.

Where cameras or additional monitoring equipment are available, the system can also be operated without continuous visual contact, but this is not a requirement for effective operation.

Safety: A Major Driver

Safety remains one of the strongest drivers for adopting robotic tank cleaning.

Although the operator may still enter the tank, exposure is significantly reduced because:

- No work at height is required

- No scaffolding is needed

- The operator remains on stable ground

- Cleaning time is shortened

This combination lowers overall risk and simplifies safety planning compared to traditional methods.

Faster Turnaround and Reduced Downtime

Manual tank cleaning often requires extensive preparation, including scaffolding, ventilation, and safety checks. The cleaning itself can take several days depending on tank size and contamination level.

Robotic tank cleaning reduces preparation time and accelerates the cleaning process. Faster completion means tanks can return to service sooner and asset availability increases.

Consistent Cleaning Quality

Robotic systems deliver stable pressure, repeatable movement patterns, and uniform coverage across surfaces. This results in more predictable cleaning quality compared to manual methods.

Reduced Water, Chemicals, and Waste

Robotic tank cleaning primarily relies on high-pressure water rather than aggressive chemicals. This reduces chemical handling, wastewater volumes, and environmental impact.

Offshore and Industrial Applications

Robotic tank cleaning is used in:

- Offshore installations

- Industrial storage tanks

- Process and reaction vessels

- Energy infrastructure

The same crawler platform can be adapted with different tools for cleaning, inspection, or measurement tasks.

Why Modular Robotics Changes the Game

Modern robotic crawlers function as modular platforms. Cleaning tools can be exchanged for inspection or measurement equipment, extending the robot’s value beyond a single task.

The New Standard

Robotic tank cleaning improves safety, reduces downtime, and delivers consistent quality. It is rapidly becoming the industry standard.

Interested in exploring robotic tank cleaning for your operation?

Get more information about the CLIIN Tank Cleaning Robot here or inquire about your specific challenges to the CLIIN Robotics team by completing the form here.