By deploying the CLIIN robot in a cargo hold cleaning configuration, bulk shipping companies will be able to replace a normal four-step cleaning process involving tons of chemicals and water with a one-step pure freshwater cleaning process.

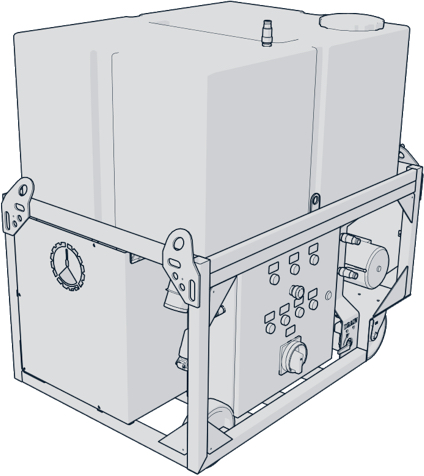

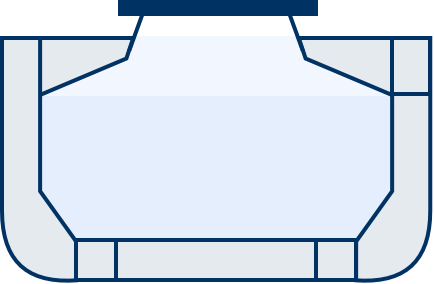

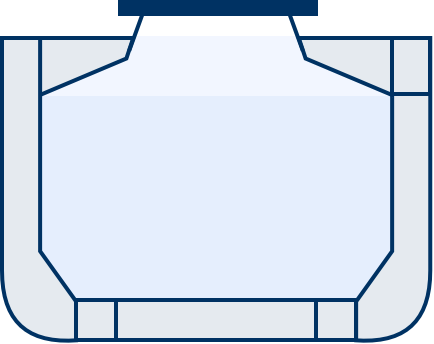

The CHR is permanently installed on board the vessel and is semi automatically operated by the vessels crew as and when required.

Apart from limiting the environmental impact, the CLIIN robot cleaning process is faster, less labor intensive and provides a significantly more effective cleaning, thus providing shipping companies a value proposition of more laden days, higher cargo intake and lower cost. Depending on operational pattern, shipping companies can expect a return on investment in less than a year.

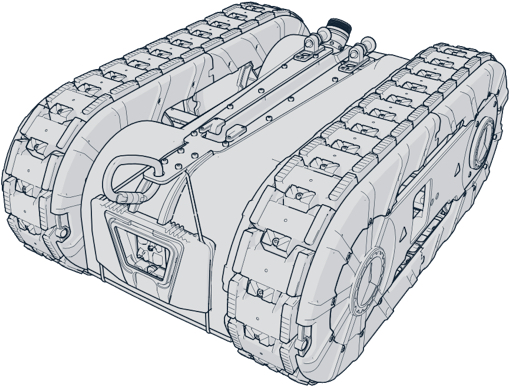

Equipped with high-pressure cleaning tools and magnetic tracks for climbing all parts of the cargo hold, the CHR ensures an efficient and thorough cleaning.

3 - 6 hours

3 - 6 hours

4 - 6 hours

4 - 6 hours

6 - 9 hours

6 - 9 hours

8 - 12 hours

8 - 12 hours